It can feel like the complexities of working at heights are insurmountable. However, by considering three main angles of attack, the risks can be identified and mitigated.

In our last blog post, we discussed all the different variables that need to be considered when working at heights. You can read that post here.

Understanding all these variables is only part of the story. Being aware of them is a good first step in improving the safety of a workplace, building or construction site. But more important is knowing how to feed that understanding into a plan, system or procedure that will put that knowledge into practice.

There are four main components of any risk mitigation solution:

Each of these components is needed by every stakeholder on a site. However, these stakeholders all have different needs, different focus and different levels of responsibility.

At Height Safety Engineers, we have distilled these down into three core areas. Each create a holistic approach to safety, starting from the most relevant point for site owners and managers, contractors and workers. These core areas are:

Creating safe places of work

Building owners, facility managers and site operators are the ones generally responsible for creating safe places of work. This is determined by looking at how duties of care are implemented when a particular task is about to be undertaken.

But what is creating a safe place of work? Put simply, it is the act of identifying and mitigating the risks associated with the site itself.

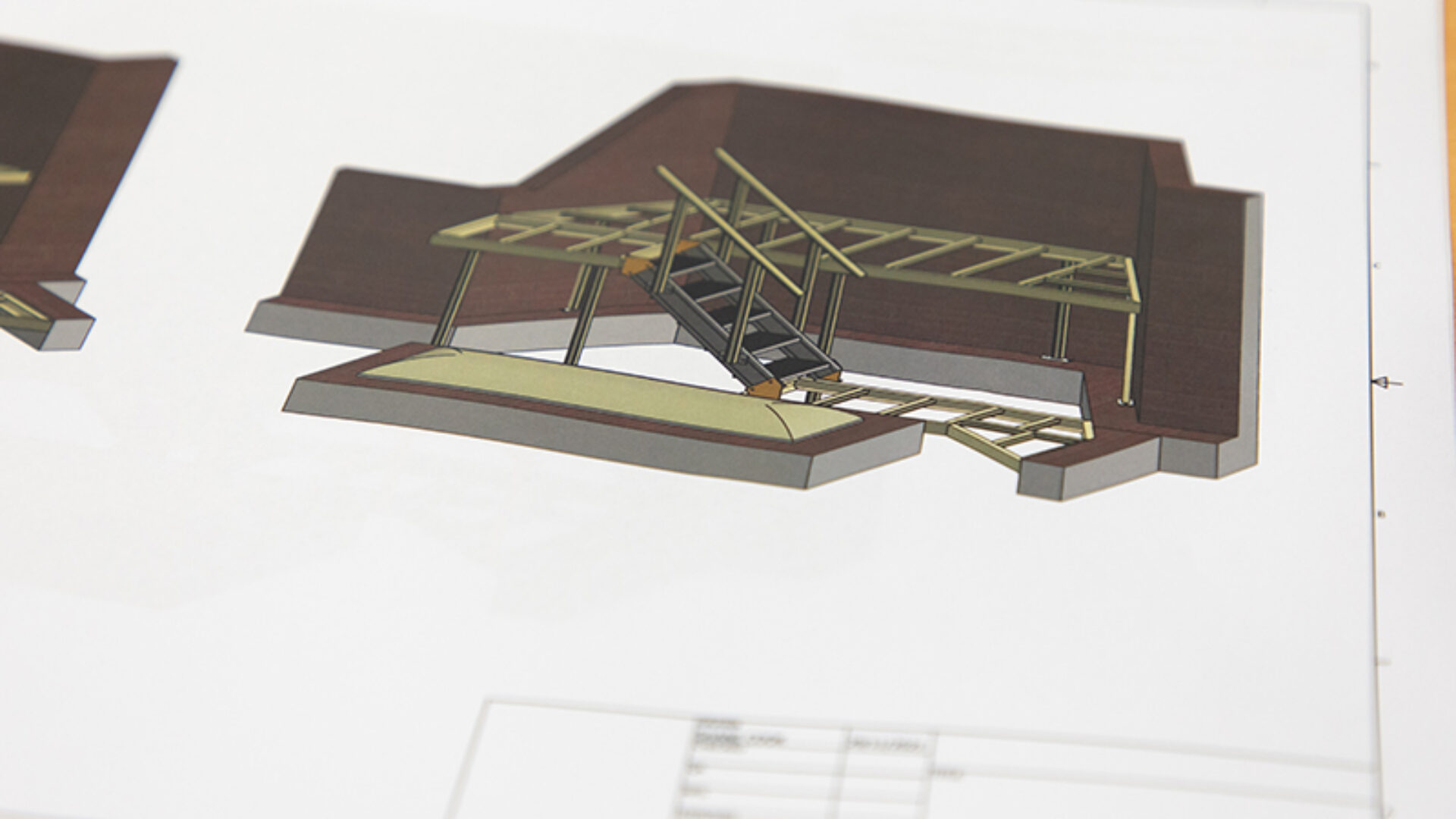

When it comes to working at heights, this could be making sure that there are safe access and fall protection systems installed on roofs, ledges and other areas where a fall is a potential safety risk.

They are also responsible for making sure these systems are maintained in accordance with the relevant Australian standards and the manufacturers service instructions. For safe access and fall protection systems, this typically involves having an annual compliance inspection (sometimes called recertification). The compliance inspection checks the system components for signs of dilapidation or damage.

It could also include having an administrative checks available that anyone entering the site needs to sign on to confirming they are aware of the safety systems in place and are trained or inducted into their use and are aware of the equipment that is required in order to safely carry out their work.

Facility and site managers should undertake height safety and other relevant training themselves. This then provides them with the knowledge of what safe work in hazardous situations looks like, so they can assist in identifying issues before an accident occurs.

This allows FMs and site managers to make sure that their site is not only safe to access, but that they are ensuring those accessing the site for the purposes of undertaking work are competent to do so.

Creating safe methods of work

For employers, contractors and service providers there is still a duty of care they are obligated to perform, but it takes on a different form. For these people, the duty relates to their workers, and creating a safe method of work for them to follow when attending site.

The method of work includes both the processes for accessing the site and performing the work. They are also responsible for ensuring work teams have the equipment they need and are trained appropriately.

Producing safe work processes and methods requires liaising with the site or facility manager (or other responsible person) about the safety systems installed on site. The system should be compliant, and documentation on its use and restrictions be made available.

Safe work method statements (SWMS) should also be given to each team member. These documents outline any risks that exist in doing the work and what steps should be taken in order to best mitigate them.

It is also important that contractors, employers and service providers develop a culture and workplace atmosphere where safety issues can be raised by their teams and addressed in an open, transparent, meaningful way.

Creating safe work practices

Ultimately, regardless of the systems installed on a site and the processes put in place by the PCBUs, it is the individual workers themselves that are responsible for conducting themselves safely.

This does not happen in isolation, however. Very rarely is a workplace accident the result of a single bad decision. Failures in safety systems and procedures are frequently a contributing factor.

Creating a culture of safety, from the top to the bottom of the work chain, is critical for preventing workplace accidents. One of the most important parts of a safety system is a team member being comfortable and supported in raising an issue before or during work. That issue should be taken seriously by their employer and the site manager. It should also be adequately addressed.

Workers, however, should make sure that they are properly trained for the work they are undertaking, in the environment where it will be undertaken. This could be at heights, in a confined space or involve hazardous substances like asbestos.

They should also ensure they have all the PPE and safety equipment they need to access the site and complete their work. That PPE should also be regularly inspected and maintained in accordance with the manufacturer’s instructions.

Working together to improve safety

Safety can only be improved if all the links in the chain are connected, and that communication flows freely from the workers up to the site manager and down again.

Site supervisors and FMs need to discuss their site safety with contractors, who need to understand the systems that are present and how they are to be used. Contractors and service provides need to ensure their teams have the processes and skills to safely undertake the work using the systems provided by the site. Workers should ensure they understand what is required of them, and make sure they implement safe work practices when out on site. They should use their training and PPE appropriately as well as raising any issues they discover as soon as possible.

Height Safety Engineers are the experts in protecting people working at heights and in high-risk situations. Our team of experts is always on hand to assist everyone from FMs, site owners architects, to service providers and contractors, to individual workers in addressing their safety needs and providing holistic safety solutions.

Start your safety journey with HSE by calling 1300 884 978 or email enquiries@heightsafety.net.