Developing and implementing safe methods of working at height for employers and contractors

Download our free height safety risk assessment toolkit. Identify your risk areas and improve your site safety.

Policies, procedures and administrative controls may feel like a burden, but for contractors and employers they are important for developing safe methods of work for their teams.

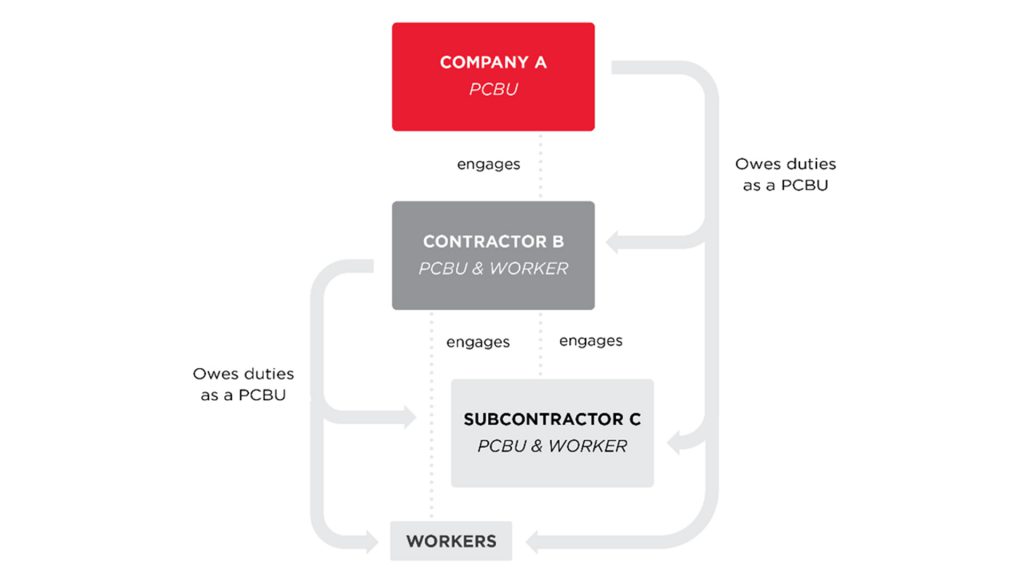

Who can be a PCBU?

Employers, contractors, or anyone organising a work team to attend a site play perhaps the most crucial role in making sure workers are protected from the risks of accident or injury while out on site.

Their role, in developing and implementing safe methods of work, involves working with a site owner, facility manager or other party responsible for maintaining safe places of work along with their own teams. They make sure that work can be completed safely and efficiently, while assisting in the identification and mitigate of risks present.

Dive into the details on our blog

Knowing what to ask of a site contact

The first thing that any contractor or employer must do before sending a team out to work on a site is to ask the contact or manager for some information about what workers are going to come across when they arrive.

When needing to complete work in areas where a safe access or fall protection system is used, plans of the system layout and usage procedures should be obtained and reviewed as part of the work planning process.

The plans and procedures should outline what type of height safety system is installed and provide guidance on its use and the equipment required to do so safely. It should also outline areas of the site where the system will not provide adequate protection, meaning that alternate risk mitigations must be considered, or the access to that area avoided completely.

Having these documents ahead of arriving on site allows contractors and employers to work with their teams to understand the safest, and most efficient, way to go about completing their work. It can also allow for the identification of other risks that may be present on site.

Ensuring that the relevant documentation is supplied by the site contact or facility manager is the first step in developing a safe method of work.

Having the right administrative controls

Safe work method statements (SWMS) and standard operating procedures (SOPs) are key components of workplace safety that should be implemented by any contractor or employer engaging in high-risk work.

The SWMS covers off typical risks that exist as part of the work process and provides mitigation techniques that can be implemented by workers to assist in staying safe. A standard operating procedure outlines the basic steps that should be followed to complete common tasks. Both these documents should be reviewed by work teams prior to starting work. This allows them to become familiar with the standard processes and tasks they will be undertaking when they arrive out on site.

Another important administrative control is a pre-start risk assessment. This can take the form of a quick checklist that is completed by the team when they arrive on site. It can cover off items such as confirming that all documentation is present and has been reviewed. It can also be a prompt to check for common issues with safe access and fall protection systems allowing workers to match the documentation against what is present on site. Any identified issues will need to be mitigated prior to starting work.

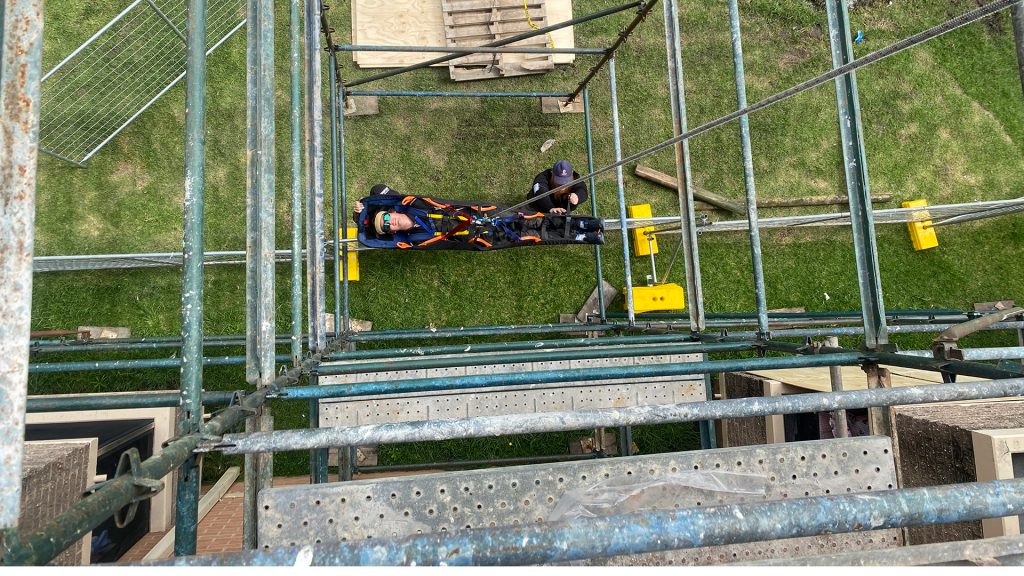

Finally, any work being undertaken in a high-risk area – whether it be at heights, in a confined space or another environment – should not be undertaken without an adequate rescue plan in place should an accident occur. Rescue plans should specify the procedures that need to be followed in the recovery of a worker following an accident as well as detailing the equipment needed to perform the rescue. No work should start without that equipment being present at the work site.

Contractors and employers should also ensure their teams have completed rescue training and are familiar with the equipment that will be used in the rescue. When accidents happen, it is vital that rescue and recovery operations begin quickly and are conducted without hesitation.

Preparing your team for high-risk work

It is the responsibility of an employer or contractor to have their team trained in the skills required to safely access work sites, complete their tasks and undertake rescues and recovery in the event of an accident.

Each team member should generally have completed a general safety induction (also known as a white card), job-specific training (working at heights, confined space, etc) and a site induction before entering a worksite.

Employers should also make sure that each team member has all the relevant equipment, PPE and tools they need to complete their job and competently utilise any safety systems present on site. For working at heights, PPE would include items like a fall arrest harness, rope line, shock absorber, lanyard and carabiners.

Most importantly, employers and contractors should be actively listening to their team members and getting their feedback on work processes and methods. Workers are the people directly exposed to safety risks at work and can assist greatly in the process of improving safe methods of work.

Creating holistic safety systems to protect people

At Height Safety Engineers, we are all about creating holistic safety systems in order to provide people with the best protection possible. This goes as much for building owners and facility managers as it does each individual worker attending a site and completing a job at height.

Improving safety takes commitment from every part of the work chain – from owners to managers and workers – to collaborate, discuss and trust that everyone is working towards the same outcome.

The experts at HSE bring decades of real-work experience in developing and implemented holistic safety systems to every job that we do. We are proud to be your partners in protecting people.

Call 1300 884 978 or email enquiries@heightsafety.net to start your safety journey with us today.