Risk assessments are a core tool of creating safe workplaces and implementing safe work methods.

Being able to conduct a useful risk assessment is a critical part of a workplace’s risk management system. Risk assessments are important in determining what hazards are present and what level of response is required of them.

Risk assessments, in one of their myriad different forms, are used across just about every industry and occupation there is – from office work through to logistics, construction, finance and beyond.

In relation to work that is undertaken at height and in high-risk environments, a risk assessment is vitally important. Protecting workers from the potential to suffer significant injuries – or worse – is one of the most important responsibilities everyone involved in the process has.

Completing a risk assessment can feel like a daunting task, but it can be broken down into smaller chunks.

Consider what and where

The first step in completing a risk assessment for your work site is take stock of the work that is going to be undertaken, and the environment it is going to be completed in.

What is the job that is going to be completed? Is it construction? Installation of plant? Gutter cleaning? What tools are going to be used?

And where is going to be done? In a factory? Up a tree? On a roof? In a glasshouse? Indoors? Outdoors?

The work being done, and its location are the two key ingredients needed to form the basis of your risk assessment. Without first considering these two things, the other steps in the process cannot be completed.

Identify the hazards

The next step can require a bit of imagination – it involves putting the work being done and the environment it is being done in together and coming up with a list of things that could go wrong or otherwise place a worker at risk of injury.

If the work is being conducted outside, will the workers be exposed to any inclement weather? Are there fall risks? If work is being done on electrical systems, can those systems still be live when work commences?

Will the work require heavy lifting? Or significant amounts of physical movement? Will it be in a confined space? Is there welding or other hot works involved?

The hazards that can exist at workplace or a job site can be as varied as the types of workplaces and job sites there are. Time should be taken to go through each step of the work being undertaken to consider what exists that could expose the worker to the potential of an injury.

Assess likelihood and severity

Once all the hazards are identified, the next step is to assess how likely they are to occur. This is paired with what the likely outcome would likely be of the hazard occurring.

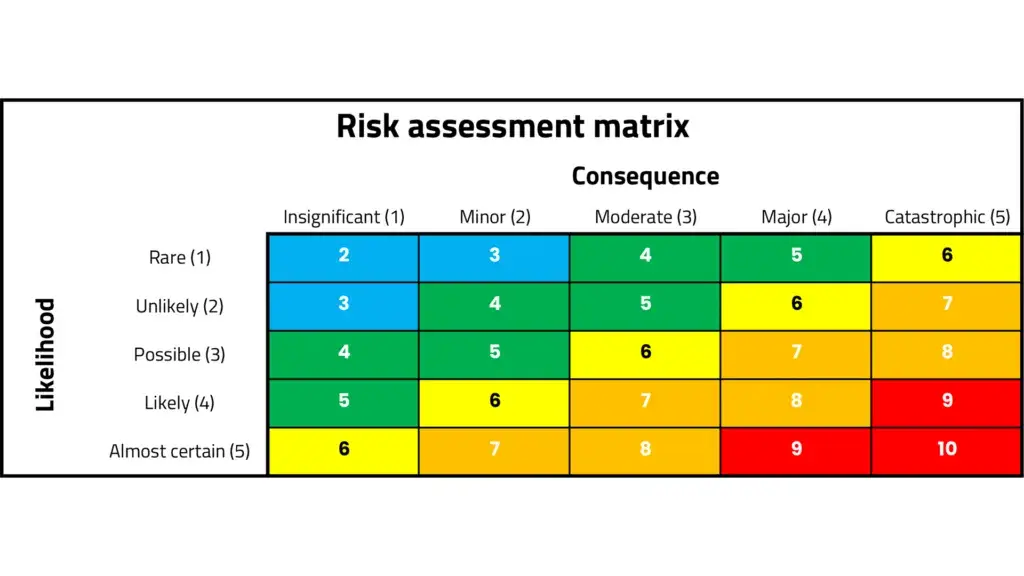

This step typically introduces the use of a risk assessment matrix. The matrix allows the mapping of likelihood and severity to then determine what the overall rating of the specific hazard is.

While there is no set format for how this matrix can look, the general form is something like this, with likelihood on one axis and severity on the other.

Each step on each axis can be given a numerical value which, when added together, can be used to place the hazard within a particular response band.

Much like identifying the hazards outlined in the previous step, this process can require a bit of imagination.

For example, while being on a roof outdoors can expose the worker to the risk of a lightning strike, the probability that will occur during any given work activity is extremely low.

A worker in the same situation getting sunburn or suffering from heatstroke, however, is much more likely.

When considering the potential consequences of a hazard, a similar process and application of imagination can be required. While some hazards (for example, falling 80m off a roof several storeys high) are easy to assess (would be fatal), others (mild electrocution) may not (would it be fatal? Might depend on who is being electrocuted).

With the likelihood and severity of the risks now mapped using the matrix, it can easily be seen which ones require immediate attention before work commences.

Mitigation of hazards

With the hazards now identified and rated, work begins on ensuring they are adequately mitigated, protecting workers from the risks of injury.

Risks rated as being the most significant – typically those with a high likelihood of occurring with severe consequences – should be dealt with prior to work starting.

The hierarchy of controls provides a framework for the development of mitigation techniques, ranging from elimination of the hazard all the way down to using personal protective equipment (PPE).

More effective controls should be considered before less effective. Each proposed control should be tested against the risk assessment matrix to best determine what improvements in safety will be as each mitigation is implemented.

Documenting safe work methods

Once all the hazards have been identified and assessed, then the mitigations determined and assessed, the results should be documented.

Generally, a worker will have a safe work method statement (SWMS) that requires review and signing off prior to commencing work. The SWMS outlines the hazards it is expected workers are going to come across and outlines how they can be mitigated.

For site owners, facility managers and others in control of a site where work is taking place, they should also have some form of documentation that outlines the hazards involved in accessing the site. It should also provide instruction on how those hazards have been mitigated, and descriptions of how any safety system that is present is to be used.

Before starting any work, workers should make sure they have reviewed and understood any documentation that discusses potential safety hazards and their mitigation. They should also conduct their own risk assessment to ensure that the documentation covers everything they need it to.

If any hazards are missing, or the mitigations incomplete, then work should not proceed.

Partners in protecting people

Height Safety Engineers are the experts in hazard identification and mitigation for those undertaking high-risk work. Our team can assist in the identification of hazards as well as the development of mitigation through safety systems, procedures, and PPE.

Discuss your safety needs with our experts by calling 1300 884 978 or email enquiries@heightsafety.net.