A guide in applying the hierarchy of controls in a work at height environment.

The hierarchy of control is a long-established process for mitigating identified safety risks that exist at workplaces. It provides a framework for working through from the most to least effective mitigation techniques available.

However, the practical application of safety measures to manage working at heights typically involves needing to use multiple controls to provide the most practicable form of protection for workers.

Principles of risk mitigation

Risks are assessed using two main criteria.

The first is how likely an accident is to occur. In terms of height safety this means, in any given single instance of a worker doing something, what are the chances they are going to fall?

Is the risk of a fall non-existent? Something which really can only ever be applicable when standing still on the ground. Or where does the probability of a fall occurring exist somewhere on a spectrum between ‘unlikely’ and ‘quite likely’?

Secondly, if the fall does occur, how severe are the consequences going to be? Again, this exists on a spectrum ranging from ‘will be slightly embarrassed’ through to ‘will be fatal’.

Once both have been assessed can an adequate plan to mitigate the risk of a fall be developed.

The aim of the mitigation that is developed in response to the risk is to ideally reduce both criteria. This makes the risk less likely to occur, and the outcome of it occurring less severe.

Elimination control

The elimination control is the only control that can be used in on its own. The reason for this is straight forward.

If the risk has been eliminated, then there is no longer any risk to mitigate. Although it is the most effective risk control, it is also the one that has a limited ability to be implemented when it comes to working at height.

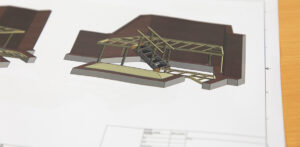

For plant such as HVAC and air-conditioning systems to be located such that any fall risk is eliminated, it must be designed with that in mind from the beginning.

The reality is that elimination is very rarely a control that can be implemented when it comes to working at height environments. The reasons that working at height must be undertaken is due to the elimination of the risk not being possible.

Layers of protection

If the need to work at height cannot be eliminated, then other layers of protection need to be implemented. The remaining levels of risk control on the hierarchy are generally used in combination with each other. That is, it is incredibly unlikely that any other single control is going to provide adequate protection for workers.

Substitution, for example, will often require administrative controls to explain how the control works and what, if any, PPE is required.

If you are substituting the need to climb a tower with the use of an elevating work platform (EWP), it will also generally require the use of PPE (harness, lanyard) and administrative controls (high risk work licence, if over 10m, and/or other training).

Engineering controls, such as a fall arrest or fall restraint system, also require the use of PPE and administrative controls (operations manuals and roof plans).

Being unable to eliminate the risk of a fall completely leaves PCBUs and workers in a position where they need to consider multiple risk controls. The process needs to find the best combination of methods for both reducing the likelihood of a fall, and/or reducing the severity of the consequences of a fall should it still occur.

Exactly what this can look like for a given worksite is going to be specific to that worksite, the amount of access needed, and the tasks being undertaken at height.

The importance of administrative control

While it may seem that documentation and administrative controls are not important, they play a vital role in identifying hazards, assessing risks, preparing workers to use and understand height safety systems.

As additional layers and control measures are incorporated into a site safety plan for working at height, the need to understand how they operate and interact with each other is critical to ensuring they work as intended.

Workers also must be aware of any limitations and restrictions that exist on any safety system used on site. Having a thorough induction and sign-on process provides the platform on which their knowledge of a site’s safety systems is built.

Roof plans and system manuals also provide important guidance on what workers will encounter when entering a safety system, allowing them to understand what other equipment and PPE they may need.

Holistic safety from Height Safety Engineers

Keeping workers protected takes a holistic approach. Height Safety Engineers are the experts in understanding and developing mitigation systems for working at height. From new buildings to plant access, solar panel and HVAC maintenance and more, HSE are your partners in protecting people.

Start your safety journey with us by calling 1300 884 978, emailing enquires@heightsafety.net or filling out the contact form on this page.