Height safety and fall protection systems can come in all different shapes and sizes. Here are some examples of what common systems can look like.

The design of two height safety systems is rarely the same. Each roof, each need for access and each working environment is different. This means that the best practice safety solution is likely to be different, too.

However, that does not mean that there are not some ideas that get shared between systems.

In this blog post, our team has put together some common aspects to height safety and fall protection systems that you may come across when working on both flat and pitched roofs.

Hopefully, being able to identify these on site will assist workers in better figuring out whether the area they are about to enter is safe to do so or not.

Systems for flat roofs

On flat roofs, workers generally do not require to be attached to a fall protection system if they are a safe distance away from the fall area. Where a fall area exists will vary from site to site depending on how the PCBU (be it a facility manager or building owner) has chosen to define one. In some circumstances it could be 2.5 metres from the edge, in others it could be up to 3 metres. Workers must always check site policies to ensure they know where the fall areas are before starting work.

In situations where access is needed only to plant, like a HVAC system, located in the middle of the roof, a system can be installed that allows for safe entry to the roof away from the edge only.

The unsafe area near the edges can be marked with something as simple as a painted line, with instructions for not crossing it included in the site induction documentation workers review before commencing work.

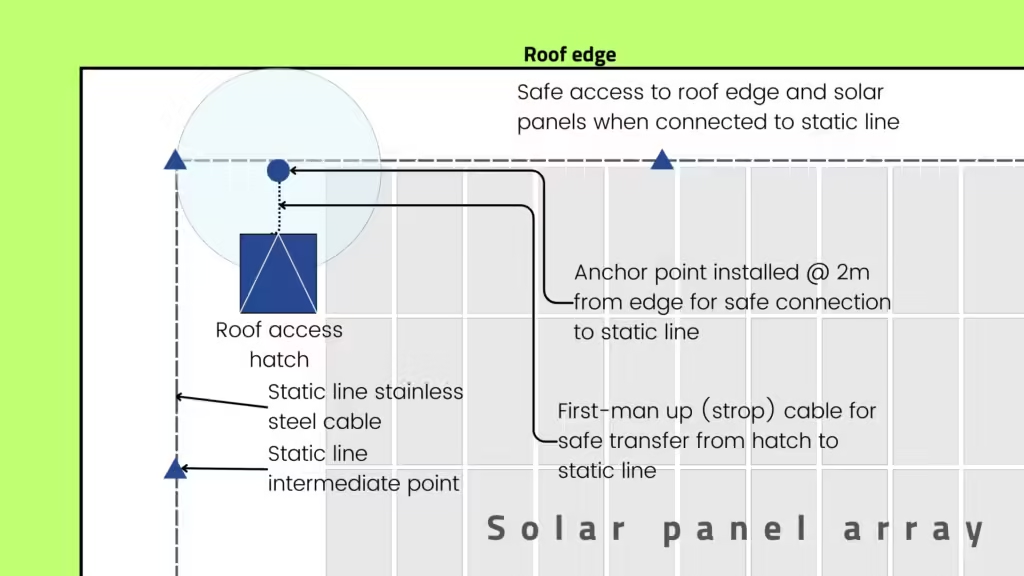

Alternately, if access is required all the way to the gutters, either a static line or anchor points can be used to make access safe by keeping workers in fall restraint. Typically, anchor points will be used as these are quick to install, require little to no maintenance and are easy for workers to use.

In situations where access is required, but solar panels are installed, a static line may be used as fewer intermediate points are required to be installed, compared to the number of anchor points needed to provide safe access the same area.

In some circumstances, a building owner may prefer getting guardrail and walkway installed on the roof. This allows workers to access the roof area without needing a harness or other PPE at all.

Not needing to don a harness or connect to fall protection systems can provide time-savings for workers as well as allowing workers without current work at heights training to safely access what would otherwise be a high-risk area.

Systems for pitched roofs

Once a roof pitch increases to beyond 15 degrees, the requirements for height safety and fall protection systems change. It is no longer possible for a worker to access a roof at that pitch without remaining permanently connected to some sort of anchor point.

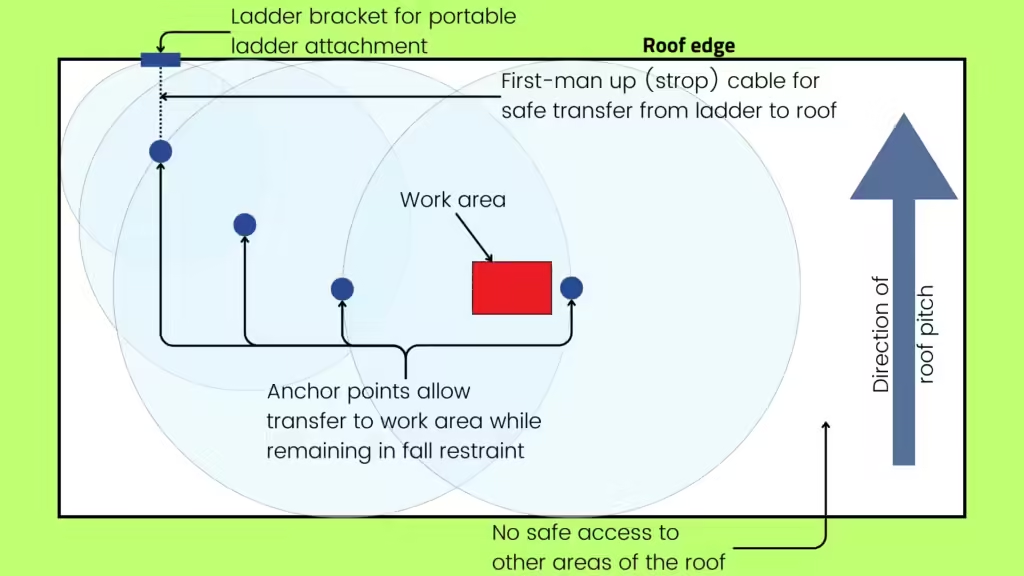

Typically, working on a pitched roof involves using a series of roof anchors to remain in fall restraint. While in fall restraint, a worker can connect to anchor point after anchor point in series while remaining unable to move beyond the edge of the work area.

Like working on flat roofs, pitched roof safety systems can be designed to either allow full access to the work area or restricted access to part thereof, depending on the needs of the building.

Restricted access systems allow a worker to stay connected to an anchor point, remaining in fall restraint, and access the area where work is to be undertaken. Venturing beyond that safe working area places the worker at risk of a fall.

If access is required to the entire roof area, additional anchor points can be installed to allow safe work positioning in any area.

Skylights and non-trafficable roof areas

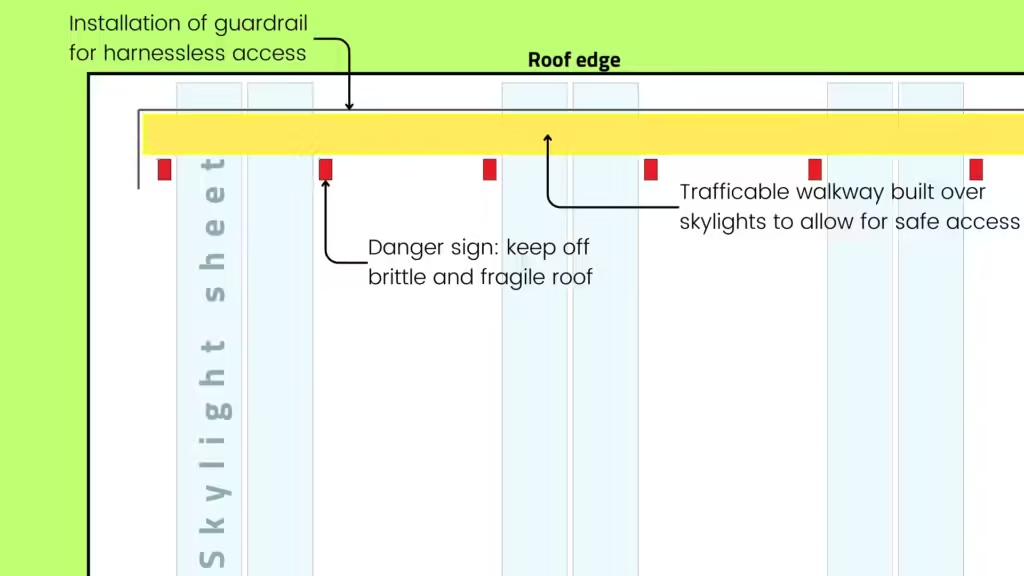

In many industrial cases, roof access requires workers to traverse over skylight sheeting or other fragile roof areas. Skylight sheeting presents a real hazard to workers as it is generally not trafficable (that is, it cannot support the weight of a worker standing on it).

To provide safe access across a roof where skylight sheeting has been installed, there are two main options, depending what level of access is needed.

If a worker needs to traverse across skylight sheeting, then typically a form of walkway is installed. Walkways are made from either aluminium or FRP (fibre-reinforced plastic) material. Both these can create a trafficable path for workers.

In some cases, there is no intention for a worker to need to travel over a skylight, however their presence on a roof still presents a fall risk. Installation of a protective mesh screen is often used in these cases. The mesh can be safely walked on, protecting the worker from a fall through the skylight should they accidentally find themselves standing on it.

These mesh screens are often used in conjunction with other fall prevention systems such as roof anchor points.

Each roof and each safety system is different

Every roof on every building presents its own unique challenges when it comes to protecting people from falls. This means that there is never a one-size-fits-all solution when it comes to getting a height safety system installed.

Height Safety Engineers have the team and the experience to assist in developing best practice, easy to use safety systems no matter the location, environment or work being completed. To find out how we can help resolve your height safety risks, call us on 1300 884 978 or email enquiries@heightsafety.net.