Every roof is different, making one-size-fits-all solutions impractical. HSE’s decades of experience can bring you custom-designed, cost-effective safe access solutions with worker safety the only priority.

For building owners and facility managers, maintaining a safe workplace is one of their most important roles. In commercial settings, these people hold a responsibility to ensure anyone coming onto their site, or into their building, can do so safely. The vast number of systems needed to keep a commercial office building operating often means that contractors and maintenance technicians can be on-site almost daily.

The systems these workers maintain and repair are often located in hard to reach, out of the way places like plant rooms, in basements and on roofs. The nature of this work – often involving needing to work with electrical systems, or mechanical plant – already carries a substantial level of risk of injury. Having this work take place in confined spaces or at height further increases this risk.

The need for safe access

Providing safe access to these areas is one way building owners, operators and managers can reduce the risk of a worker suffering a serious injury, or worse, while carrying out their job.

One important aspect of providing safe workplaces for these critical workers is understanding that every single building is different. Access to plant rooms and the location of services differs in every single case. Put simply: providing safe access cannot be adequately accomplished with a one-size-fits-all solution.

The experts at Height Safety Engineers have the experience and know-how to design a safe access solution tailored to the specific needs of your building. Utilising a wide range of system components from Australia’s leading suppliers and manufacturers of height safety and fall protection equipment. We ensure your workers are kept safe.

Once your system is in place, our NATA accredited recertification team can help make sure your building remains compliant with all relevant Australian standards and legislative requirements over the lifetime of your fall protection system.

So, how do we do it? Here is a look inside the HSE process from a recent job we completed in Parramatta, NSW.

Step 1: Site visit

After the initial contact from the client, we conducted a thorough site inspection.

At the site inspection, our experts are walked through the access needs of the building, seeing the area in which maintenance technicians and contractors will be working first-hand.

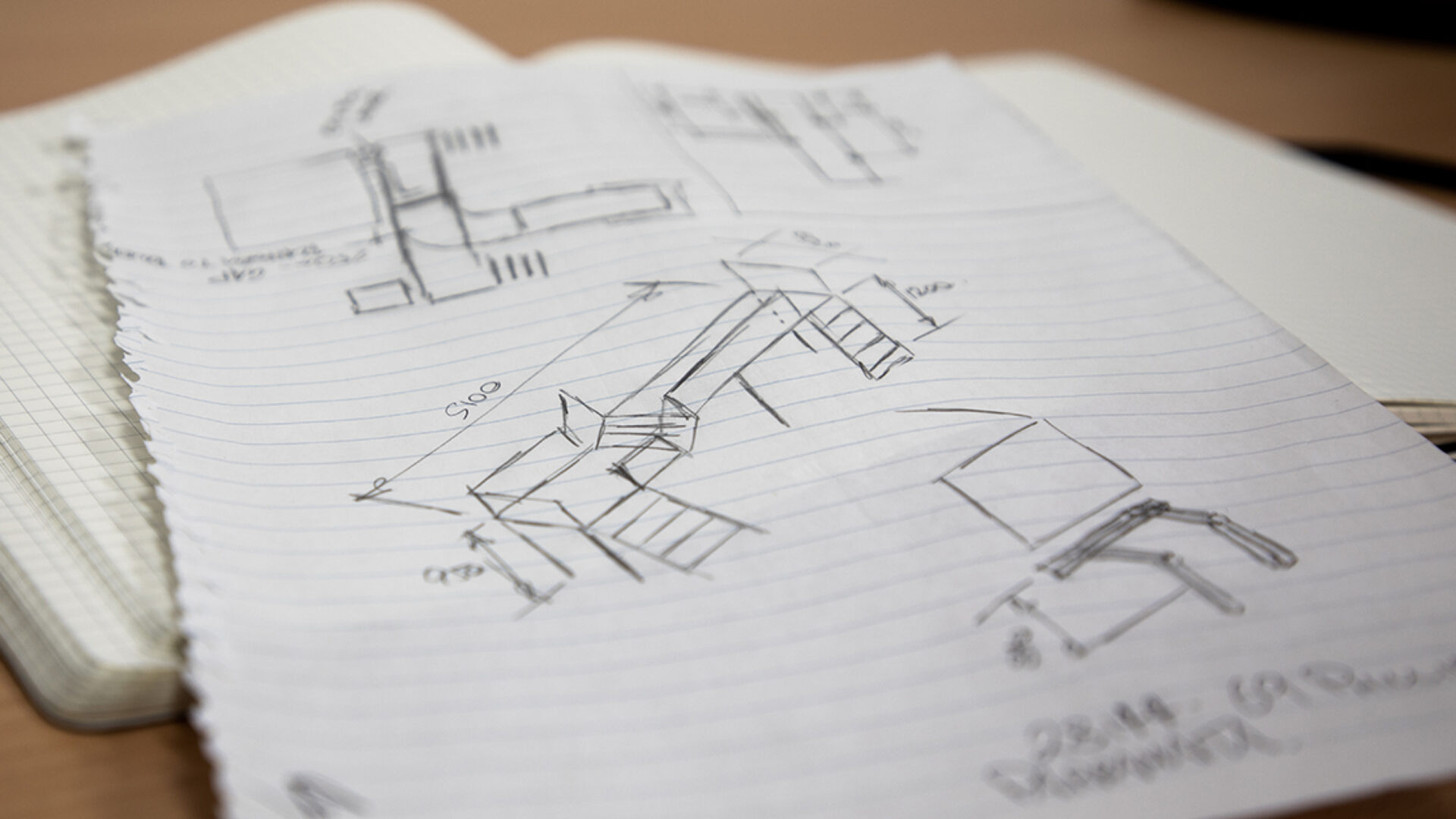

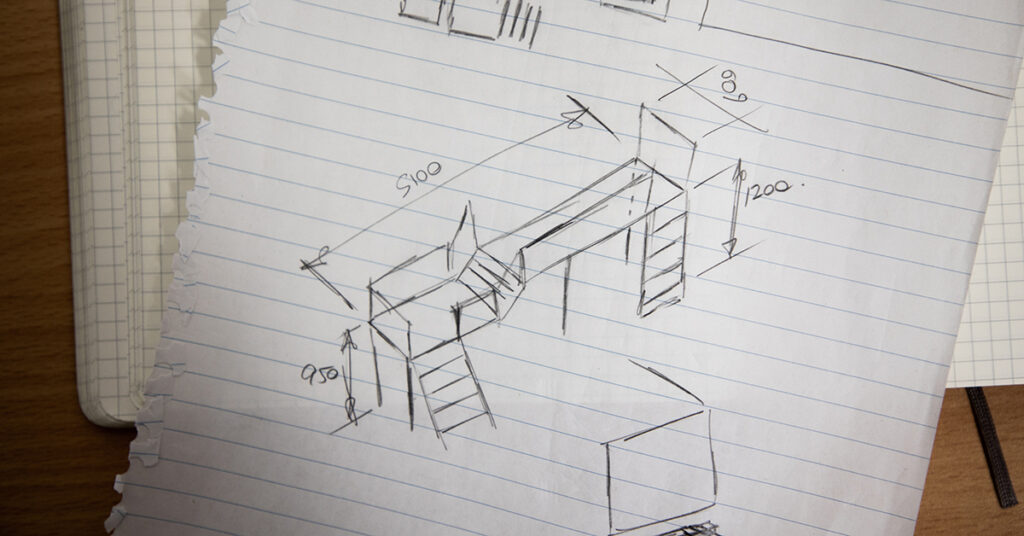

During this site inspection, our estimator took a series of measurements, then quickly drew up a sketch showing a conceptual design for an access system that would easily solve the building’s safety issues.

The sketch assists in helping our designers understand the needs of the building, but also in giving the owners, managers or operators an idea of how their system can be integrated into the existing structure.

With the sketch complete and the concept signed off by the client, attention turns to the next stage.

Step 2: Detail design

Back in the office, the site measurements and sketch are used to put together a final, detailed design.

At this stage, our designers put together the drawings that take the ideas presented in the sketch and formalise them.

This process also confirms the exact list of components that are going to make up the system, with our team able to select from a vast range from Australia’s leading suppliers and manufacturers of fall protection components.

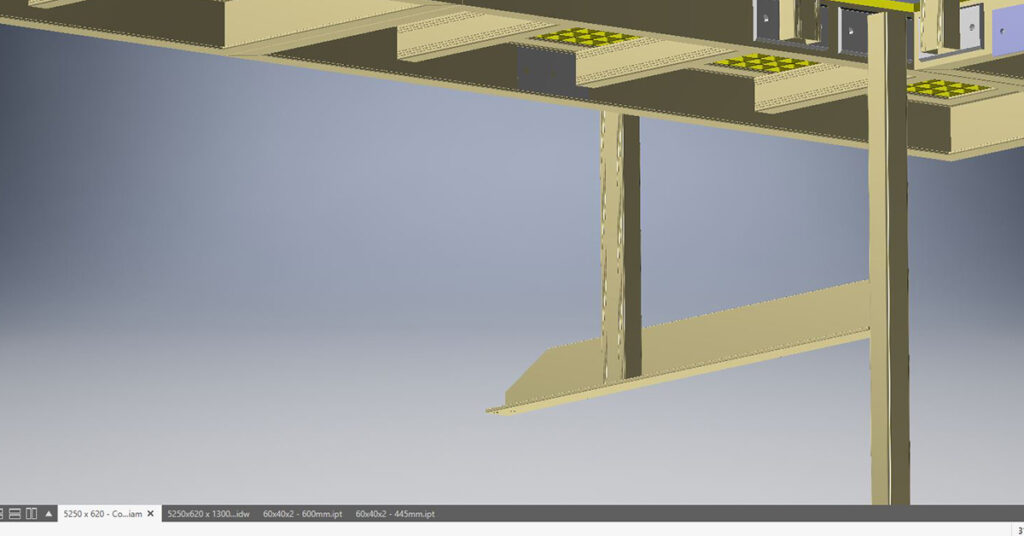

For this system, the need to integrate the new platform into an existing structure required it be rendered as a full three-dimensional model. This allows our designer to see the complete picture of how the system will work with the existing structure and give them the ability to work out the best solution quickly and accurately.

Once the design is fully detailed, the various components are either ordered or, in some cases, sent to our workshop to be fabricated. The system is then booked for installation.

Step 3: Installation

With the design finalised, components ordered and fabricated the only thing left to do is install the system on site.

Depending on the location, size, and complexity of your designed system, the time taken to complete the installation process can vary. Our team will make sure that communication with you is open and honest so that you are fully informed throughout the process.

When the installation is complete, your system will be certified as compliant and ready to use. And while at this point you are close to the end of the journey, there are still a couple more things that you need to consider to further improve the safety of your staff, contractors, technicians and site visitors who are going to be using the new system.

Step 4: Follow up

Simply knowing you have a system installed is not the end of your fall protection journey. As the building owner or facility manager, the responsibility you have to protect worker safety is ongoing. Like most other parts of your building, regular maintenance in required to keep your system operating at its full efficiency.

Under Australian standards, fixed fall protection systems need to be inspected and recertified on a regular basis by a competent person. The amount of time that can lapse between recertification inspections will vary depending on the location of your system and how regularly it is used, but the standards outline a gap of no longer than 12 months (one year) as the absolute maximum.

All team members, contractors and site visitors that are going to be using the system should be trained in its use, and more generally in working safely in areas where there is the risk of a fall. An individual’s skills and knowledge when it comes to working in high-risk environments is just as important as having systems and equipment in place. If a worker does not know how to use the system, the system may not work as designed in the event of a fall.

Finally, you should be aware of any additional personal protective equipment (PPE) that may need to be used in conjunction with the system. For example, to be able to use fall arrest anchor points, a worker will need to be wearing an appropriate harness with shock pack to assist in absorbing the impact of a fall. They will also need a rope line and carabiners to ensure they can safely move around the area the system is installed.

Keeping people safe at work is everyone’s priority, and there is no silver bullet. It is only by taking a comprehensive look at your site or building’s safety needs can you know that you are doing everything practicable to ensure everyone gets to go home at the end of the workday.