When developing methods of protecting workers from the hazards that exist on a work site, the hierarchy of control is the standard tool used to find the most effective method.

The hierarchy of control is an important part – perhaps the most important part – of putting together a risk management plan. It assists in understanding the most effective mitigations to put in place when conducting a risk assessment.

While the hierarchy of control is a universal tool used for assessing risk mitigation, there are a couple of different versions that you might come across depending on your workplace. They all cover the same information; it is just conveyed in different ways.

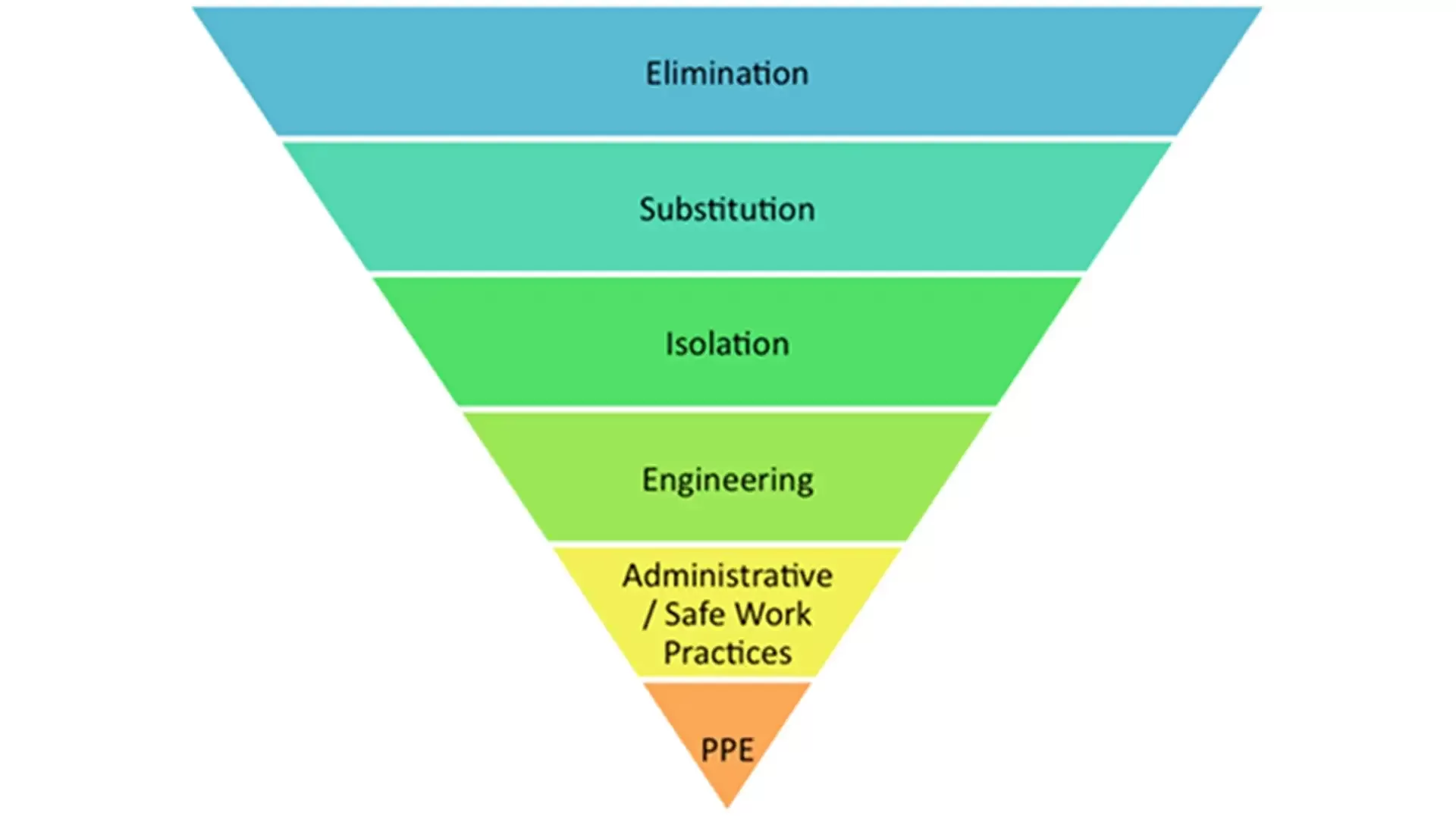

Often presented in the form of an inverted pyramid, the hierarchy of control provides a framework that prioritises more effective risk controls.

Eliminate the risk

Eliminating the risk involves removing the risk from the workplace completely. This is always the safest course of action.

For example, if the risks are associated with working at height, there may be ways to complete work while staying on the ground. This eliminates the risk of a fall.

In many cases, however, eliminating the risk will just not be possible. Where this is the case, the next most effective control must be considered.

Substitute the risk

Substitution involves replacing the original risk with one that is less hazardous. While it means there is still a risk of an accident occurring, the chances of it occurring would be less as well as the potential severity being reduced.

Examples of substituting the risk are using things like scaffolding or an elevating work platform to access areas at height instead of a ladder. While the risk of a fall still exists, as work is taking place off the ground, the likelihood of a fall from an EWP or off scaffolding is significantly reduced compared to that of a ladder.

Isolating the risk

Isolating the risk involves putting in demarcation to ensure people not associated with the work remain clear of the work area.

This could be anything from a barrier to some signage or warning tape.

Depending on the exact hierarchy of control document being used, this one may be present, or its functions may be incorporated into the engineering controls.

Engineering controls

Engineering controls involve developing some sort of physical safety system the worker can use to minimise the risk of an injury.

A lot of the work undertaken by Height Safety Engineers would be considered an engineering control. Installing an anchor point system on a roof is common for working at heights situations.

Engineering controls generally work in partnership with both administrative controls and PPE to provide a more thorough safety system for workers.

Administrative controls

Administrative controls are the work procedures, system manuals and other documentation that can be involved in high-risk work.

This documentation could be anything from a safety system’s usage manual to a checklist that asks whether a worker has completed certain units of training prior to entering a site to start work.

Personal protective equipment (PPE)

PPE is the last control on the hierarchy. This is the protecting equipment that is work by a worker including items such as harnesses, hard hats, gloves, protective overalls, glasses and more.

Needing to use PPE is an acceptance that the hazard cannot be fully mitigated, and the worker will remain at some risk.

Working with asbestos is a good example of this. Undertaking work in areas with asbestos contamination – even the removal of asbestos – requires the worker to be at risk of inhaling fibres. There is no other way to remove asbestos than to disturb it.

PPE provides a protective layer between the worker and the asbestos fibres, but asbestos fibres are still going to exist in the area. The risk is still present.

Understanding your safety risks

The hierarchy of control is only useful if the risks associated with a workplace or job site are known and understood. Risk management processes are an important part of workplace safety.

Discuss your safety needs with the team at HSE by calling 1300 884 978 or email enquiries@heightsafety.net.