The inhalation of dust and particulate matter created during building or maintenance work presents a significant health hazard to workers across all industries.

The creation of dust and other particulate matter that can become airborne is something that is largely unavoidable when completing building, construction, or maintenance work. It is created when all sorts of materials are cut, drilled, or taken to with a grinder.

Some particulates, asbestos fibres for example, have been known to be hazardous for over 30 years now. While the hazards presented by other dusts and particulates – like crystalline silica – have only become known more recently.

Like many other types of hazards in the workplace, there are times when the creation of dust or particulates is unavoidable. In these situations, it is vital that correct and compliant mitigations be put in place to protect workers, other building occupants and the public.

What is asbestos?

Put briefly, asbestos is the collective name for a range of naturally occurring silicate mineral fibres. These fibres were used in a wide range of building and machinery products.

Its widest use occurred during the 20th century, while its effects on health were known. Although its use started to be phased out in Australia through the 1970s and 80s, it was not completely banned until late 2003.

Asbestos was an incredibly versatile substance and at the time of peak use was found in everything from building insulation and cladding to hair dryers and cosmetics. Perhaps most famously, the snow used in the Wizard of Oz film was made of pure asbestos.

Inhalation of asbestos fibres poses a significant risk to a person’s health. Fibres embed themselves in the lungs and, over time, can cause fatal respiratory diseases and cancers, including mesothelioma.

What is crystalline silica

Like asbestos, crystalline silica is a naturally occurring substance. It is a type of silicon dioxide, a substance that is one of the most abundant on the planet found in soil, rocks, and sand. The most common form of crystalline silica is the mineral quartz.

Crystalline silica is also a prominent component of manufactured stone. This type of stone has been used extensively in kitchen bench tops. It is also a core component of bitumen, grout, glass, and cement.

Silica dust is created when workers chip, drill or grind objects that contain silica, including crystalline silica. Like asbestos, these dust particles can become airborne and, when inhaled, embed themselves in the lungs.

While any single exposure to crystalline silica dust can lead to serious health problems, the probability increases dramatically with repeated exposure.

Minimising dust and particulate creation

Like any workplace hazard, the risks of exposure to asbestos and other dangerous particles can be mitigated by applying safety controls. Determining what controls can be used is done through completion of a risk assessment and application of the hierarchy of controls.

As is ever the case, the best protection against exposure to dust and particulates is to not use materials that create dust and particulates. When it comes to using stone and stone products, that could involve getting pieces pre-made offsite thus not requiring any cutting, or drilling to be completed as part of the installation process.

If drilling, cutting, or grinding material is required, then dust is likely to be produced and efforts to minimise or capture it should be made. This can include the use of different tools, utilising dust capture and extraction machines, using water to keep the point of cutting or grinding wet to stop dust becoming airborne and cleaning tools regularly to clear them of excess dust and particulate.

Minimising the spread of dust and particulates

Even if controls are put in place to minimise the creation of dust, efforts should still be made to limit the spread of any dust or particulates that are generated. The best way to go about this is to isolate the area where the dust-creating work is taking place.

If the working area is indoors, steps should be taken to seal off the area from the rest of the building, and the outside. This includes looking doors, windows, vents, exhaust fans and any other way airborne particles and dust could spread beyond the controlled work area.

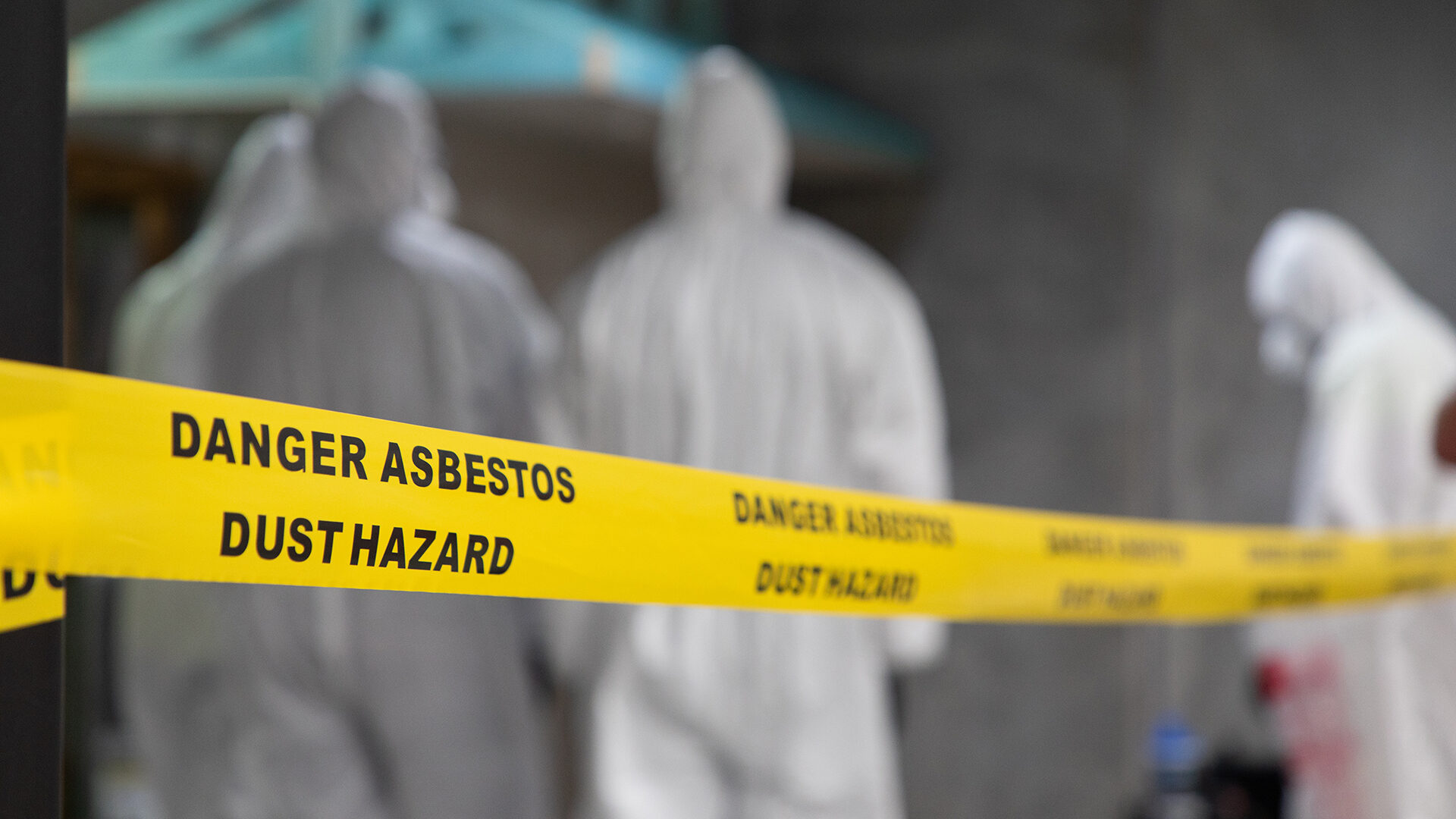

Care should also be taken when it comes to clothing. Dust and particulates can attach themselves to a worker’s clothes, which are then taken off-site, back home and all places in-between. The best protection against this is the use of protective coveralls. These are worn over the top of regular clothes and removed at the conclusion of work, prior to departing the controlled area.

Mitigating inhalation risk

All control measures relating to dust and particulates are to reduce the likelihood that airborne fibres and particles are inhaled by a worker or other person. Along with all the measures that can be taken to limit the creation of dust and its spread, specific PPE is also going to be required to add a further layer of protection.

Generally, this takes the form of a face mask. Masks come in a variety of shapes and types, each with specific benefits, drawbacks, and scenarios they should be used in. When it comes to working with hazardous substances like crystalline silica and asbestos, the face mask chosen should be designed for those specific particles and fibres. It should also form a complete seal around the mouth and nose – this requires it be fit tested.

Protective eyewear should also be used. Although we do not breathe through our eyes, dust and fibres can still make their way into the body through the eyes. Humans tend to touch their faces often. It is a subconscious action, and a very easy way for hazardous substances to be transferred from the hands to the face.

Identification is key

Understanding where the risks of dust and particular exposure – especially asbestos and crystalline silica – are and what to do if it is present at a worksite is the most important step that can be taken to mitigate the risks of exposure.

11084NAT Course in asbestos awareness and 10830NAT Course in crystalline silica exposure prevention are nationally accredited training courses that provide detailed information on what the dangers of these substances are, where they are typically located, what to look for before you start work and how exposure prevention controls can be implemented.

For those needing to conduct work on asbestos containing materials 10852NAT Course in working safely with asbestos containing materials provides skills and techniques for being as safe as possible while working in situations where the risks of asbestos exposure are greatest.

Partners in protecting people

Height Safety Engineers are the experts in providing safety solutions for high-risk work. Discuss your dust and particulate extraction and protection needs with our PPE team or by calling 1300 884 978 or emailing enquiries@heightsafety.net.

More information about our training courses can be found on our website:

- 11084NAT Course in asbestos awareness

- 10830NAT Course in crystalline silica exposure prevention

- 10852NAT Course in working safely with asbestos containing materials

Height Safety Engineers are your partners in protecting people.