Compliance inspections and system recertification

Conducting regular recertification and compliance inspections on safety systems is a crucial part of standard building maintenance.

Regular compliance inspections on safety systems are an important part of every building’s planned preventive maintenance schedule. Safe access and fall protection systems are vital for mitigating risks faced by workers, and should be kept in proper working order at all times.

Safety systems like these can tend to be “out of sight and out of mind”, especially if they are only used a handful of times a year. Systems located outdoors – on roofs or other external areas of a building – can be corroded by exposure to the elements. Changes to the building structure, either through damage or just the passage of time, can also place a system in a state where it may not function as intended.

Height Safety Engineers can conduct compliance inspections on a range of safe access and fall protection systems, no matter their use or location. We provide detailed reports showing any areas where a system is not compliant and can help in putting together a remediation plan to implement fixes and return the system to a compliant state.

What is a compliance inspection?

A compliance inspection – or sometimes called recertification – is a check on a safe access or fall protection system to ensure it is still in good condition and has been installed correctly.

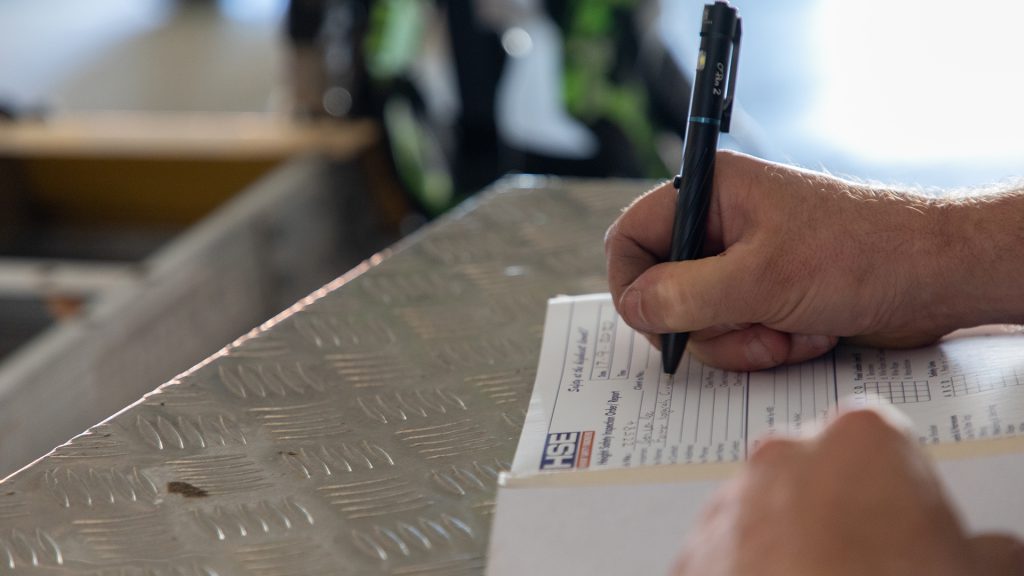

During a compliance inspection, an experienced height safety technician from HSE attends the site and physically checks each individual component of the system. They look for damage, corrosion and other signs of degradation, as well as that its fixture to the building or structure is still solid.

For systems with roof anchor points installed, the inspection also covers their layout. This makes sure the anchors have been placed in such a way that a worker can be kept in fall restraint while using the system.

The technician takes photographs of the system and records their observations. Once the inspection is complete, there are two possible outcomes for the system.

If no issues are found, the system is marked as being compliant. After the paperwork and photographs are reviewed, a certificate is issued to the system owner.

In the event problems are found with the system, the technicians notes and photos are compiled into a report. The report outlines the issues with the system, citing the relevant sections of the standards they have failed against, and proposes rectification or repair work that should be completed prior to using the system again.

When are compliance inspections needed?

Safety systems should be inspected on a regular basis. Workers should be conducting checks of the system, as well as their equipment, before every use. Damage to a system can occur at any time. No worker should use a system that is damaged

Maintenance actions, like a compliance check, should be completed on a regular schedule. Often, this is done annually, in line with the recommendations of the Australian standards. However, there may be circumstances where a more frequent schedule may be required.

Some systems can be located in areas where the environment is particularly harsh, in these cases it may be necessary to increase the inspection period to be more frequent. This would assist in shortening the time period between a problem first forming and it being discovered.

Similarly, if a safety system is used regularly, more frequent compliance inspections may be required. Systems that are frequently used are more likely to degrade as a result and should be checked more often to quickly identify any potential issues that may arise.

Why are inspections needed?

Compliance inspections form an important part of a building or site’s planned preventative maintenance program. Bring critical safety systems, they should always be kept in full working order so that should an accident occur the worker is best protected against the risks of an injury.

The AS/NZS1891.4 standard governs the inspections and maintenance of safe access and fall protection systems. It states that “items of equipment which are in regular use shall be subjected to periodic inspection and where applicable, servicing”. These inspections should be carried out in accordance with the manufacturers instructions, but should really be completed at least annually.

Learn more about compliance on the HSE blog

Got a height safety question? Ask our team

Why work with HSE

Height Safety Engineers is NATA accredited for compliance with ISO/IEC 17020. We have the widest scope of accreditation of this type within the height safety industry. HSE is holds certifications for ISO45001 OH&S management system and ISO9001 quality management system.

On average, our technicians have spent a decade each working in the height safety industry. Our combined experience on working with safe access and fall protection systems is well in excess of 100 years.

The safety of those working in high-risk areas is our first priority. Each inspection we undertake on a safety system is thorough, and we provide detailed updates on the status of the system. Complaint systems are issued with a NATA-accredited certificate of compliance.

If our team discovers any issues with the system, HSE provides a detailed report showing how those issues relate back to the relevant sections of the Australian standards. The report also provides the required work needed to be undertaken to repair the system and return it to service with minimal friction.

Understanding where fall risks are

All too often, the risks of a fall from height are not considered until it is too late. It is also common for safety systems to be out of sight and out of mind a lot of the time. If the risks and systems are not fully understood or considered properly, it is very easy for a worker to find themselves in unsafe areas without realising what they are doing.

It is important that everyone, including the facility manager, building owner or any other PCBU understand the risks that exist at a workplace. A height safety audit goes further than a simple compliance inspection of any existing system to identify and assess what risks are present on a site.