Safe access systems

Safe access systems work to provide workers a way to enter roofs or other raised work areas while mitigating the risks of a fall. They facilitate the completion of tasks such as plant maintenance and roof repair work.

Safe access systems provide a method through which workers can locate themselves as well as their tools and equipment on a roof or raised area. They allow this to happen in a way that mitigates any risks of a fall from height that a worker may be exposed to while doing so.

Safe access systems can take on many different forms and use a variety of components depending on the area being accessed, the work being conducted and the frequency at which access is required. Like all safety systems generally, there is no “one size fits all” approach to safe access. All systems should be designed and installed to best suit each individual circumstance.

Like fall protection systems, and safety systems more generally, the components used to construct a safe access system can vary depending on the needs of the system being designed and installed. They can include things like ladder brackets, fixed ladders, stairs and more.

Types of safe access systems

There are a variety of different safe access systems available. Which one is needed for a workplace will depend on a number of factors including the frequency of access, the location where access is needed and the type of work being undertaken in the area the system is used to access.

A common type of system used for infrequent access is a simple ladder bracket, paired with a first-man up cable (FMUC, sometimes called a strop) and a roof anchor point. While a worker is required to use a portable ladder to complete the system, this system allows easy and safe access to single-storey roofs where access is infrequent. The other benefit of a ladder bracket is that when the system is not being used, access to the roof is restricted. This makes the roof safe as it cannot be easily accessed by someone who is not authorised to access it.

In areas where access to a roof or other area where the risk of a fall from height exists is required more frequently, and perhaps access to the general area is more restricted (for example, a factory or industrial facility), the access system might be comprised of a fixed ladder. Fixed ladders mean that access to the work area is always available, and means the worker does not have to bring a portable ladder with them to the site.

Stairs with guardrail can be used in areas where the need to restrict access is lessened and where access is required at higher frequencies. The other benefit a safe access system like this has is that users of the system may not require the use of any additional personal protective equipment (PPE) such as a harness or lanyard.

Safe access systems can also be used inside buildings to access areas including mezzanines and roof spaces. Gaining access to a roof storage space can be achieved using a fold down staircase. These types of stairs sit in-between fixed and temporary access. Usually they are able to be folded out of the when not in use, but can be easily put into place should access be required.

Safe access system components

There are a range of common system components that workers may come across when using a safe access system. Many can be installed either to an existing building, but others work better when incorporated into a building’s design from the start of planning.

Common safe access system components can include:

Ladders

Ladders are often used in situations where permanent access is required to an area at height, but where it may be impractical to install stairs or another fixed access system. Depending on the requirements of the system, the type of ladder used can vary. A ladder may also be installed to allow movement from one level to another, for example between levels on a roof.

A typical aluminium step or run ladder would be installed. In some circumstances there may also be a vertical lifeline installed alongside the ladder to provide fall protection while ascending or descending the ladder. A first man up cable (FMUC) may also be present at the top of the ladder to provide fall protection as the worker transitions from the ladder to the roof section or access platform.

First man up cables

The first-man up cable (FMUC) is a steel cable permanently attached to an anchor point. These are typically used when transitioning from a ladder to roof. The worker attaches a lanyard to the cable and it works to provide fall protection while they reposition themselves from the ladder to the platform, roof or other working area. Once there, they disconnect from the cable and attach themselves to the anchor itself or other fall protection system that may be present.

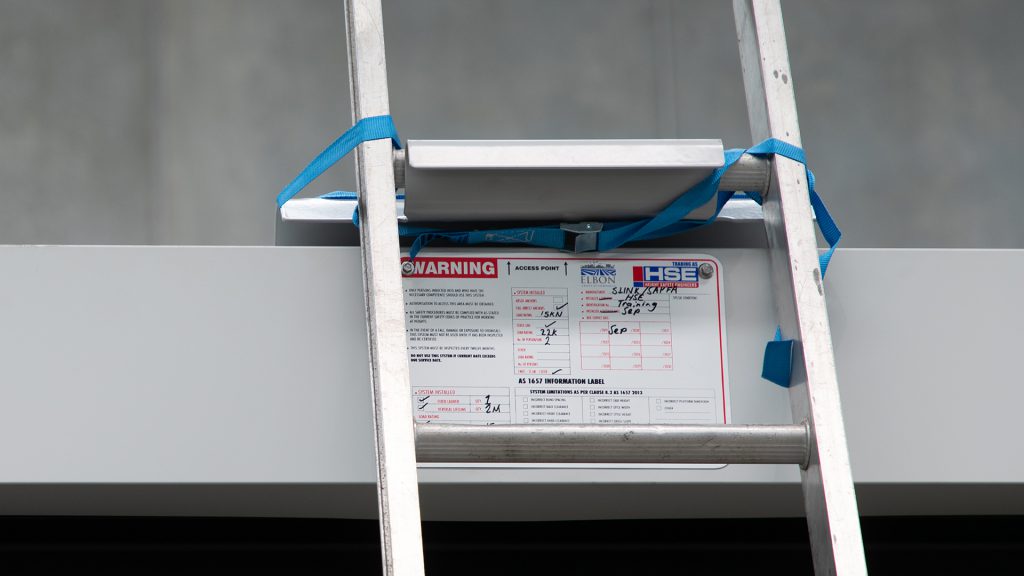

Ladder brackets

Ladder brackets are permanently fixed brackets, placed on the edge of a roof, into which a temporary ladder is placed to allow access. Once the ladder is placed in the bracket, it can be firmly secured to avoid falling away. The worker can transition to the roof using a first-man up cable to provide fall protection while doing so.

Temporary ladder brackets are also available for placement in areas where a fixed ladder bracket may not be available, but access using a portable ladder may be required.

Stairs

It might not be something that stands out to people as being a safe access system, but stairs can be one of the most practical, easy to use safe access systems there is.

Like most other safety system components, there are a different types of stairs available that suit different purposes and different locations. While stairs are typically associated with moving between levels inside a building, they can also be placed outside a building or other workplace to allow external access.

The main advantage of having stairs as your safe access system is that usually the worker is going into an area that does not require the use of additional PPE, such as a fall arrest harness or other work positioning equipment.

Designing for safe access

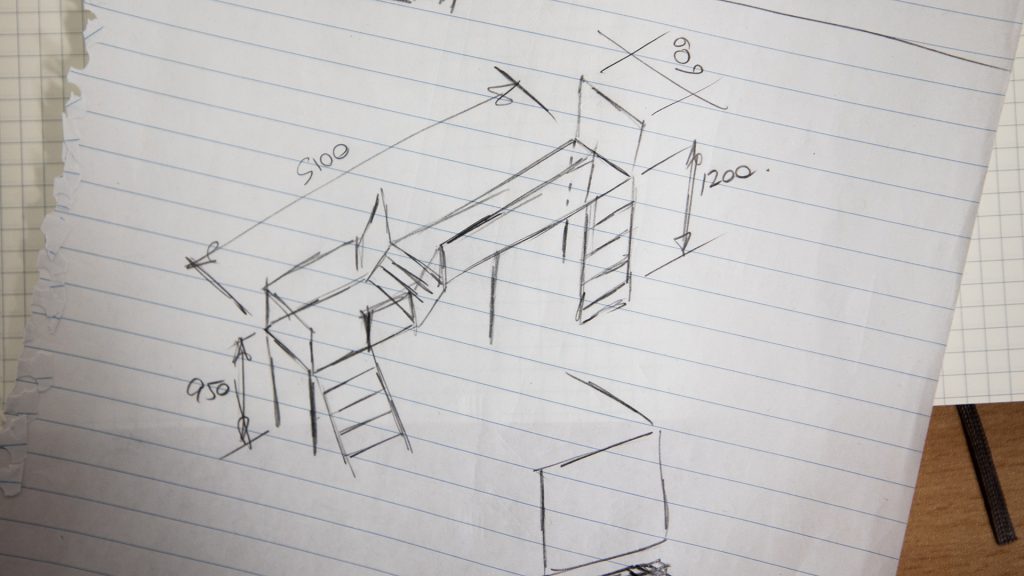

One of the best ways to ensure that a building has safe access where it is needed is to consider the access needs of workers during a building’s design stages. Although compliant systems can always be designed and installed after construction, there are cases where a better, safer system that is easier for workers to use could have been included if it were considered during planning.

Having a compliant safe access system included as part of a building’s plans can provide immense benefits to everyone in the chain, from the developer to architect or engineer down to the builder and even individual workers.

For developers and building owners, the biggest benefit is removing a significant variation cost from your plans. This allows for more accurate, complete tendering from builders. Often, safety items associated with working at heights and safe access are left until a building’s construction has started before they are properly considered. Depending on the needs of workers and other aspects of the building (for example, solar panel installation), the costs for a compliant safety system can be substantial and unplanned for. Working with an experienced height safety company, like HSE, to get your access systems designed while a building is still on the architect’s desk can assist in making sure that when a tender is received for construction it is much more accurate and complete.

Tendering more accurately is also a benefit for builders. This makes it easier to fully understand what the likely cost of a project is, as well as the timeframe needed to complete it. Further to this, depending on the construction schedule and type of system included in the design, some aspects of the safe access and fall protection systems may be able to be used during construction itself. This creates benefits in not having to include temporary systems and can create efficiencies in the installation of some plant and equipment in areas where the system has been installed.

Integrating safe access and fall protection systems into building design is also of benefit to architects, building designers and engineers. It assists in making sure that conflict between services, safety and building design are resolved before concrete starts being poured. Having a process through which potential conflicts between competing service needs are identified ahead of time, allows for a more considered resolution to be designed. This can occur in a way that does not slow already-started construction.

For workers, being able to use an installed access system during construction can provide safety benefits over a temporary system. This can make work safer, and let it be completed more efficiency – significantly reducing the risks associated with the work.

Maintenance and compliance

Just like all other aspects of a building, access systems are required to be maintained to make sure they keep operating as they are intended. For many safe access systems, this maintenance takes the form of a regular compliance inspection (sometimes these are referred to as recertification inspections). These checks make sure the structure of the system has not been corroded or damaged and that the system was installed according to manufacturer specifications.

Height Safety Engineers compliance inspections are NATA-accredited, providing peace of mind that the system has been thoroughly checked by a recognised expert. Any deficiencies or non-conformance in an installed system is reported, with a proposal supplied for rectification works to bring the system back to a compliant state.

Safe access as part of a holistic safety system

Providing safe access to working at heights areas is just one component of a safety system. Creating a safe workplace requires taking a holistic approach, and considering the needs of the people who are directly exposed to fall risks.

Safe access systems must work in concert with documentation that describes its use and checks the training levels of workers. Workers must understand the system, how it is to be used and its limitations, while also having relevant skills to complete their work safely.

The PCBUs at a workplace or site should also work to ensure that other aspects of safe working at heights systems are provided where the risk of a fall exists. These should be complemented by a comprehensive set of administrative controls and checks to ensure that only once all aspects of safety have been checked that work begins.

Got a height safety question? Ask our team

Safe access FAQs

Those responsible for people needing to gain roof access or work at heights are required by law to provide them with a safe working environment. This means, at any given time, multiple people may be responsible for different aspects of a worker’s safety.

For employers of these workers, that responsibility could include ensuring their work processes ensure risks are mitigated or managed. It could also mean making sure their employees have adequate training, so they have the skills needed to work safely at heights or in other high-risk areas.

With regards to roof access, the responsibility for this is with the building owners or facility managers of the location the work is due to take place. Depending on the circumstances of the work, this could mean the buildings require the installation of a fixed roof access system to help ensure maintenance or other tasks undertaken on the roof can be done so with minimal risk of a fall occurring.

Responsibility for providing safe access rests with the person conducting a business or undertaking (PCBU). There can be several PCBUs at once for a workplace, each with a different but related duty of care for specific aspects of the site and the work being conducted.

A builder or facility manager might have a duty of care over an entire building or work site, while a contractor may owe a duty of care to their workers and subcontractors.

What is most important, is everyone involved in the job to take a proactive approach to safety, and work to resolve any issues and mitigate any risks that may be discovered.

This is difficult to answer as safe access systems can take on my guises depending on where they are installed, the types of work they are facilitating and the frequency at which access is needed.

Infrequent access might just require a simple ladder bracket and a first-man up strop cable to allow for safe access, while more complex access needs may need an engineered solution like a fixed ladder or even stairs.

Consulting a height safety specialist will ensure that your access needs are met with the most practical, cost effective and compliant system.

Depending on the system and the work being planned, it is possible that training may be required.

There are a range of safety skills that every person should have, but when it comes to working at heights there are some specific training courses that should be completed.

The first is a general induction (or white card). Secondly, anyone needing to work in areas where there is a risk of a fall should complete work safely at heights training. This is critical in teaching foundational skills in risk assessment and safe work procedures for working at height.

Finally, workers should be inducted into any specific system that are required to be used.