Safety systems

Height Safety Engineers are the experts in the design and installation of safe access and fall protection systems for workers at height and near confined spaces.

Falls from height remain one of those most common causes of workplace injury in Australia. However the risks associated with working at heights or in areas where a fall is possible are often downplayed or not understood in the first place.

While it is ultimately safer for workers to simply not work in areas where fall risks are present, in many circumstances this is simply not possible. Working at heights is an unavoidable part of many industries from construction to plant maintenance. In those situations where work must be completed at height, a bespoke safety system is often required. This is where the team at Height Safety Engineers can help.

The Height Safety Engineers experts are your partners in protecting people. We can assist in providing system design and installation for safe access and fall protection. Our designers bring decades of real-world experience to every job. We also work closely with leading system manufacturers to provide holistic safety systems for building owners, engineers, architects and facility managers.

By taking advantage of the holistic approach Height Safety Engineers have to safety, facility managers and building owners can rest assured that not only will their system be fully compliant with Australian standards – a key step in meeting their responsibilities as a PCBU – but that procedures can be supplied and training provided to system workers to ensure there are no gaps in the safety chain.

Height Safety Engineers can also supply consulting and concept designs for architects, engineers, craftspeople and building designers to assist in making new buildings as safe as possible before the first sod is turned on site.

Safe access systems

Safe access systems allow workers to effectively and efficiently perform maintenance and repair work that needs to be undertaken in areas not easily or commonly entered. They allow workers to locate themselves and their equipment on a roof or other area where a fall risk is possible to perform work.

These access systems can take on a variety of different forms depending on their location, the frequency of access and the distance of the height that needs to be traversed.

Fall protection systems

Fall protection systems work to mitigate the risks of a fall from height while workers are completing their tasks in areas considered to be at height. These systems can also be known as work positioning systems, and like safe access systems can come in a variety of shapes and sizes depending on their location and the work being undertaken using one.

Fall protection systems generally provide either fall restraint (avoiding the fall occurring) or fall arrest (limited the height of the fall), and may or may not require the use of a harness or other PPE.

Safety systems for new and existing buildings

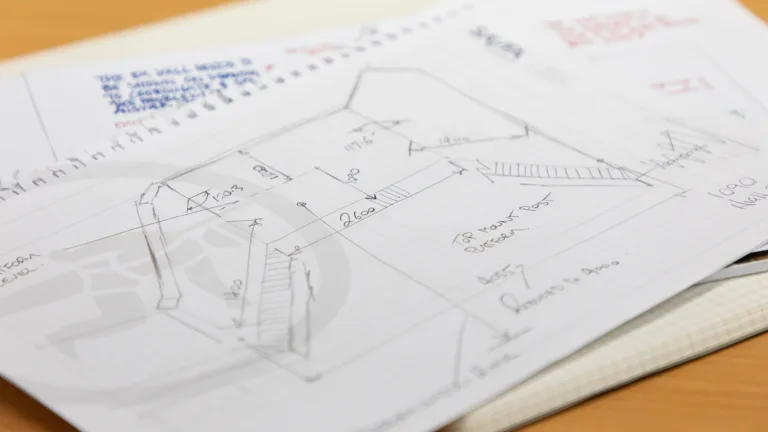

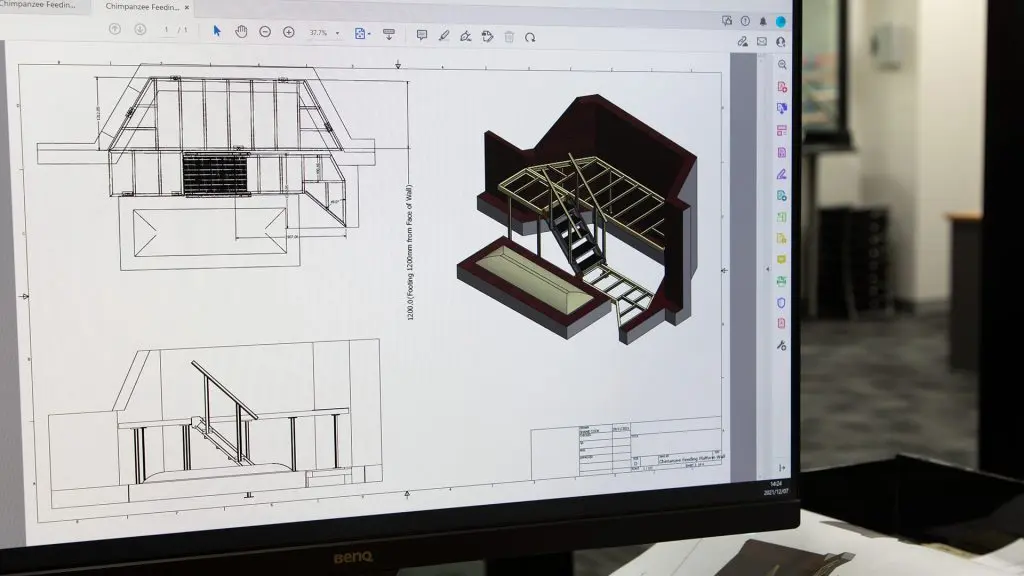

The needs for a safety system can exist for both existing buildings and buildings that are still on the drawing board.

Height Safety Engineers work with architects, craftspeople, building designers and engineers to sure that new buildings will be safe for workers from the first day they arrive on site. Integrating compliant safety into a building’s planning stages often allows a more comprehensive safety outcome to be achieved.

In some cases, as the safety systems can be installed during building construction, those systems can be used to protect workers installing plant or facade components. This allows for easier installation, saving time and money for all parties to the project.

For existing buildings, especially older ones, it is often the case that access and maintenance needs change over time. When this occurs, a building may need to have a new safety system designed. In situations where there is an existing system, it may need to be upgraded in order to be compliant with the new access or fall protection needs. To ensure access needs are adequately met, a safety audit may be required to understand the risks around the current state of the building and its safety systems.

HSE's holistic approach to safety

At Height Safety Engineers we take a holistic approach to safety, and encourage our clients to be proactive and engaged with the whole safety chain – everyone from building owners and facility managers, down through contractors and service provides, to the individual workers who are ultimately the ones accessing high-risk areas and using safety systems.

Having a safety system installed is just one solution to one part of the safety puzzle, not the answer itself. A safety system must work in concert with documentation that describes its use and checks the training levels of workers. Workers must understand the system, how it is to be used and its limitations, while also having relevant skills to complete their work safely.

Contractors and service providers should be fulfilling their duty of care to their workers by having a comprehensive set of safe work procedures. They should also ensure their workers are trained and have been supplied with all the correct safety equipment and PPE they need to correctly use a safety system and complete their work.

For workers, they need should understand that, ultimately, they are the ones that are accessing the high-risk areas. They should make sure that everything is in place to best protect them while they go about their work, and raise issues with safety when they are first noticed. Gaining skills in risk identification and assessment can be done through training, and by checking the documentation provided by the system owner and the employer’s safe work procedures marry up and cover off what can be seen on site. Workers should also ensure their equipment and PPE is well-fitted and suitable for the work they are doing.

Only once all the pieces of the safety puzzle have been addressed should work commence.

Height Safety Engineers can assist the entire safety chain in making sure they have adequately mitigated their risks and that duties of care have been followed.

Learn more about safety systems on the HSE blog

Safety system maintenance and compliance

Like all other aspects of a building – from electrical to HVAC and guttering – safety systems need to be regularly maintained. Annual compliance inspections (sometimes called recertification) are a critical part of ensuring that safety systems are kept in good working order, are compliant with the current standards and have been installed correctly.

Systems found to be compliant by inspectors from HSE are issued a NATA-accredited certificate. If deficiencies are found, a report is prepared and rectification work proposed to bring the system into a compliant state.

Safety system FAQs

Height safety systems are designed to allow workers safe access to roofs and other areas, and to provide fall protection whilst work is being completed.

Safe access and fall protection systems come in different shapes and sizes, depending on the individual needs of the workplace they are being installed into and the types of access required.

Height safety systems can either be based around a fall arrest style system or be a fall restraint one – both offer different advantages and disadvantages depending on the working being completed.

All height safety systems should be built to, and installed in accordance with, the relevant Australian standards and codes of practice.

Fall arrest provides maximum freedom of movement for a worker. However, in doing so it also enables the worker to reach a position where a fall from height could occur. In the event of a fall, the safety system works to catch them and minimise the distance of the fall.

Fall restraint works, when used correctly, by preventing a worker from getting into a position where a fall from height is possible. This can be accomplished in different ways. The most common way is through the use of a fixed-length lanyard attached to an anchorage point. The length of the lanyard is selected to be such that it does not allow the worker to reach a fall hazard.

There is no “one size fits all” solution when it comes to height safety systems. Every building is different, and the system required should always be designed with that in mind, along with the needs of the workers that are going to be accessing it.

Some safety systems could be compliant with only the installation of a ladder bracket, some signage and a single anchor point. Others may require more complex, engineered, solutions comprised of walkways, static lines, guardrails and other components.

At Height Safety Engineers, our focus is always on providing the most appropriate and best practice solution for both the system owner and those workers that will be using it. All our systems are custom-designed to ensure the most effective protection is provided.

Safety systems should be provided by anyone responsible for people working at heights on a roof or other area where a risk of a fall exists.

This could be a building owner, or facility manager, that requires workers to access the roof for the maintenance of plant an other equipment (e.g. air-conditioning units) or to perform gutter cleaning.

Under the Work Health and Safety Regulations 2011 (C’wth), the “…risks to health and safety associated with a fall by a person from one level to another that is reasonably likely to cause injury the person or any other person” are required to be properly managed and mitigated by the person conducting a business or undertaking (PCBU) at a workplace.

All workers should be trained in the relevant skills that are needed to safely complete their tasks. Typically, there are three basic levels of training that should be completed prior to starting work in a high-risk area.

A general safety induction should be completed as the very first step. In must jurisdictions in Australia, this is commonly referred to as a white card.

Secondly, the worker should have been completed task-specific training. This training can differ depending on the most likely risks that are going to be faced by the worker – whether they be the risk of exposure to asbestos, the risks of a fall from height or the risks associated with working in and around confined spaces.

Finally, all workers should be inducted into the systems being used on the site where work will be carried out.

These three levels of training ensure that workers have the skills and understanding they need to safely complete their work.